Well, the mercury reached 106 degrees Fahrenheit on the California coast a few weeks ago. I’ve lived here since the late 80s and can’t remember ever seeing the temperature hit that level. In fact, I looked it up and the previous record high for that day was a comparatively frigid 90. It was so hot that my iPhone shut down when I had the temerity to use it outdoors.

Yes, summer is here.

While waiting for my smartphone to chill out, I began wondering about the aircraft I fly at work and whether it needed any weather-proofing. It doesn’t matter if you’re trusty steed is a Light Sport aircraft, helicopter, jet, or something else – like any piece of equipment, it’s probably going to suffer in extreme environmental conditions. We’re all aware of the powerplant limitations, as they’re usually placarded on a gauge sitting directly in your line-of-sight. But there are a variety of lesser-known ones which can bite in very hot or cold weather.

When I started flight instructing, one of the most surprising things was the number of airframe temperature limitations found in our fleet. The Diamond DA-20 airframe had a limit of 55°C. A structural temperature indicator was installed on the spar bridge behind the aircraft seats to alert the pilot when it was too hot to fly. The Extra 300’s has a 72°C limit and a similar indicator on the main spar carry-through.

Sometimes the limits are on the other side of the dial. The DA-40 DiamondStar airframe has a minimum temperature of -40°C. One might wonder why you’d want to fly when it was that cold, but in my experience once you’re underway (read: warm), winter flying can be a heavenly thing. And seeing as how the airplanes are built in Canada, I’d be willing to guess that a least a few DiamondStars have actually encountered that limit.

I can hear the gleeful refrain from pilots of metal aircraft, as they appear to be immune from such concerns. But I would counter with a story about the time I flew out to Death Valley to rescue a fellow Skylane pilot whose tires had literally melted into the pavement at Furnace Creek. Whether the limits are published or not, they’re there.

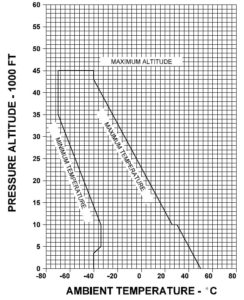

The -40°C figure seems to pop up frequently on the Gulfstream. That’s the minimum oil temperature for starting the engines. It’s also the minimum fuel temp. There’s a minimum for turning on the cockpit displays and systems (18°C), a temperature below which the the life rafts must be removed (-28°C), and even one for removal of the main aircraft batteries (-20°C). That’s something you don’t see in glossy promotional photos of $50 million long-range business jets: a frostbitten guy struggling to remove the aircraft batteries because the ambient temperatures are just. too. cold. Even the airframe has limits, as this charts shows.

Business jets have potable water lines, storage tanks, and lavatories which must be protected from freezing. The galley contains a mind-boggling variety of other items ranging from carbonated beverages to chocolate snacks which will melt, freeze, crack, or snap under environmental extremes. Foodstuff may sound like a minor consideration, and I suppose it is. But few dozen exploded soda cans could cause thousands of dollars in damage to a bizjet’s interior, not to mention the injury to a pilot’s career.

Speaking of the pilot, I’d be remiss in not mentioning that there are practical limits for humans as well. If the hardware is suffering, odds are the aviator is as well. Our biological temperature limitations are more insidious because they can’t always be measured on a gauge. But they’re every bit as important as those for our equipment – perhaps even moreso, since nearly 90% of accidents are caused by failures of the pilot rather than the machine.

So during this sweltering summer, remember to take good care of your aircraft – and even better care of yourself.

If the crew gets a hotel room then the gewizz deserves a heated hangar. If one isn’t available then reposition the aircraft. Color me naive but it worked for me for 40 years. I’ve gotta say that the life raft limit is one I never thought of. There’s always something interesting in your posts.

Glad you found the post worthwhile, Doug! And I agree, the airplane deserves a roof over its head. Unfortunately, some of the airports we fly to don’t have hangars large enough. Many FBOs with hangars seem to run out of space quickly when the weather is sour–and it doesn’t help that many of our flights are short-notice affairs. The nature of 135, I guess. At others, like Teterboro, where we do have a couple of hangar slots, they’re usually occupied by company aircraft in maintenance. It’s a shame, because a hangar can make a miserable weather day almost… pleasant.

Having just graduated into heavy iron (Global) I really appreciate the time you take to (re)evaluate what it means to operate those in the weird North American scenarios we see. Thanks for the very well written article Ron!

Thanks! And congratulations on your Global type. I had the opportunity to spend some time in the cockpit of a Global 6000 equipped with the Vision avionics suite, and it was pretty impressive. I felt like Mr. Sulu seated on the bridge of the starship Enterprise. My Gulfstream IVSP felt rather antiquated by comparison. Kind of unfair to compare a mid-80’s design to the latest-and-greatest from Bombardier, but I suppose we all do that from time to time. 🙂